► Inside the Renault Metaverse programme

► Major digital overhaul of manufacturing process

► Driving efficiency, making factories sustainable

Renault is undertaking an audacious programme to digitise its entire production process – from first design sketches to the final car rolling off the forecourt into the clutches of its first owner.

Most car makers are accelerating their digital programmes, but Renault’s is so advanced that it opened its doors to CAR magazine to showcase what it calls the Renault Metaverse.

You’ve doubtless been watching the travails of Facebook parent Meta, which is spending billions on its Metaverse. Well, Renault’s is here and now and is a way of connecting digital touchpoints across 35 factories worldwide and bringing them to life for the company’s staff to understand the data. It’s catchier than its formal name: the Industrial Data Management Platform 4.0 (IDM4).

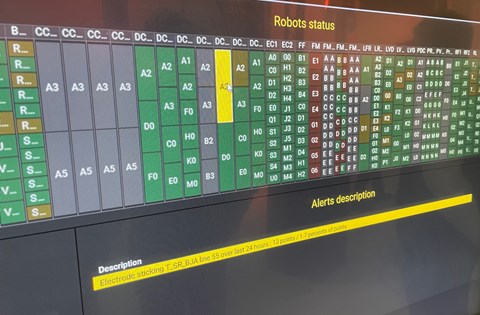

So instead of hanging out with your mates and laughing at their avatars, Renault’s Metaverse is about connecting and visualising its data so staff can make better decisions. Or to give a concrete example: supervisors are alerted via their tablet if a robotic welding machine has stuck on a car and can arrange a fix (see alert below) – or track the dispatch of cars to dealerships and alert customers if their new vehicle is delayed.

Renault started work on the programme in 2017 and claims it’s grown into the ‘first industrial metaverse in the world.’ The system uses technology from the gaming industry to bring the data to life for staff, visualising reports and alerts in a more actionable way than a dull spreadsheet ever could.

What is the purpose of the Renault digital programme?

What is clever about Renault’s data management platform is the interoperability of its datasets. Or in plain English: it is endeavouring to ingest every data point into its system – currently one billion datasets per day, across its own facilities and those of suppliers.

If you’ve ever tried to migrate your iPhone data to a new Android device, or flip your photo archive from one supplier to another, you’ll know how hard data portability can be.

For Renault, which built 2.7 million vehicles last year, it’s a logistical nightmare: every robot, factory, connected object or digital touchpoint belonging to the Renault Group has its own unique ID, allowing it to communicate with the Renault Metaverse.

Today more than 70 percent of the group’s industrial equipment is connected and they’re aiming for 100 percent. It’s truly the internet of lots of things.

End result? Renault says it can track virtually anything: the weather and traffic conditions to predict the punctuality of parts deliveries to its factories; monitoring energy usage across every site and identifying rogue machines or processes that guzzle kilowatt hours; it’s even set up a data control tower, creating the equivalent of automotive air traffic control to make sense of it all.

What are the benefits?

This ambitious digital programme is a key pillar in the company’s drive to become more efficient, lower costs and cut waste – all objectives of the Renaulution turnaround strategy to boost profitability at the French car maker.

Renault claims it is already driving cost savings of 20-30 per cent, boosting quality and allowing it to cut wastage and CO2 emissions by using artificial intelligence to spot trends that humans might miss.

Between 2022-2025, Renault forecasts savings of €320 million (£280m) in fixed and variable costs, halving the amount of CO2 produced per vehicle in production, speeding up delivery to customers and cutting warranty claims by 50 percent by ironing out wonky production glitches.

Jean-François Salles, who oversees the supply chain for Renault globally, told CAR: ‘To give you an example, we have 6000 trucks on the road every day and by monitoring the weather and traffic, we can predict which factory will be impacted. We have already saved 8000 truck journeys by better planning.’

Welcome to the brave new world.

Renault swaps cargo ships for sailing boats to send cars across the Atlantic