► We drive electric conversion with a difference

► BEDEO and Protean Electric in-wheel motor tech used

► How does the motor tech work in the real world?

The idea of an in-wheel electric motor has been with us a long time. Benefits are said to include accurate wheel control, more power and grip and much less intrusion into passenger space compared to a more traditional electric car setup.

That is what engineering firms BEDEO and Protean Electric have been working with for quite a while now, and have started entering the massive world of converting classics to use electric power. The first example its teams have converted is a Defender, and we’ve driven it.

At a glance

Pros: Smooth performance, uninterrupted off-road ability, minimal changes to original vehicle

Cons: Tech is still commercially exclusive, BEDEO only works with conversions, it won’t be cheap

What’s new?

Let’s talk about BEDEO first. BEDEO is an engineering company that acquired Protean Electric in 2021, a tech firm that has been at the centre of the UK’s engineering efforts surrounding in-wheel electric motors for years. Protean Electric has designed, developed and engineered its own in-wheel motors, as well as battery technology and automotive engineering since 2009 – its partnership with BEDEO has widened the firm’s reach in the UK and beyond. The team’s engineers manufacture and assemble their own electric powertrain in-house, including the battery pack and componentry.

BEDEO has commercial partnerships with companies like DPD, DHL and Ocado for converting combustion-powered delivery companies into electric ones using its own technology, and it has also worked with Stellantis in 2019 to electrify some of its commercial vehicles. In-wheel motors by Protean Electric also powered the NEVS Emily GT – a project that was created in part by former Saab engineers.

Given the firm’s commercial partners and standing with other OEMs, it’s proud that it’s engineering stuff with tough and useful feedback from said partners. There’s no regulatory body in the UK for managing EV conversions, but Protean Electric CEO, Andrew Whitehead says that the team work to stringent safety standards influenced by its operations across Europe. ‘Today in the UK, I could set up a garage, go to scrap heap and rip out modules and batteries and whatever I wanted to [to put into an EV conversion], but with 400-volt DC electrics, you don’t get a second chance.’ So much so that the team work to the IATF 16949 technical specification that rules on quality management internationally.

Reborn Electric: Icons is the newest venture within BEDEO and Protean Electric. As the name may suggest, the aim is to design ‘plug-and-play’ electrified powertrain conversions for both commercial and passenger vehicles. The team say the focus is ‘to retrofit iconic, well-loved vehicles sold in large numbers worldwide to drive on electric power.’ Its new Icons range starts with the original Land Rover Defender, ‘and we’ll certainly bring this to new icons in the future,’ Whitehead tells us.

Why a Defender first? The team say they’re legendary enough to be memorable and desirable conversion targets, but not too rare that converting one would be seen as sacrilege. Older generations of the Porsche 911 are being posited as a potential future conversion, which isn’t a new concept – we’ve driven an electric 911 conversion from Everrati.

What about the specs?

For the Reborn Electric Defender, the engine and driveshafts have been chucked out and a battery and four in-wheel motors have taken their place. BEDEO says the swap has meant no ‘excessive additional weight’, and the aim is ‘to electrify without compromising load space and enhance performance and reliability.’

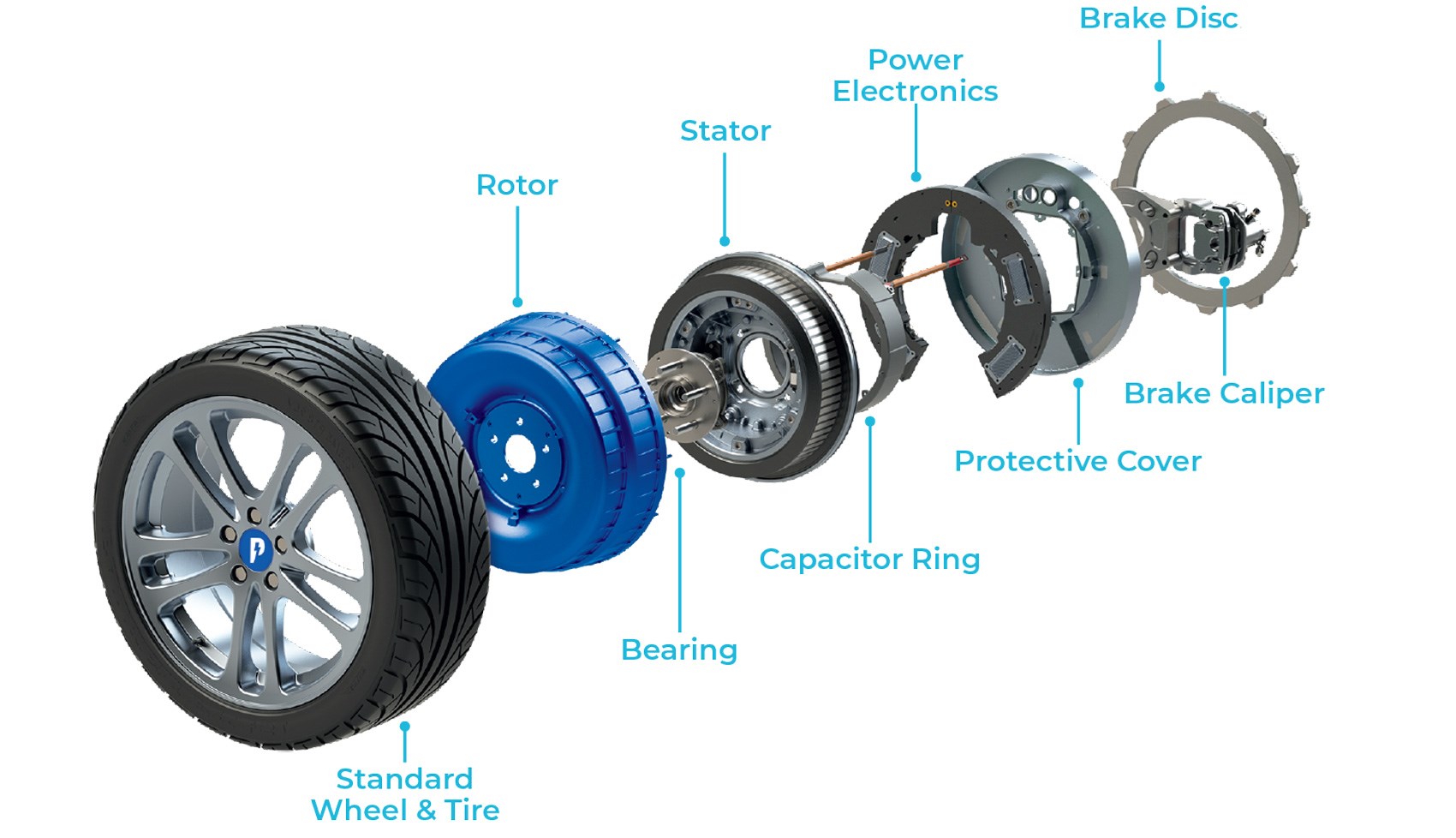

The Defender we’re driving uses Protean Electric’s in-wheel motors. These permanent magnet e-motors physically sit inside the wheel hubs, and incorporate the rotor (the component you physically see looking through the wheel), stator, electronics and brakes all into one unit. ‘We have the rotor on the outside because that gives us the most torque available,’ says Whitehead, ‘and we use the wheel bearing to centre the rotor around the stator.’ The physical, friction brake discs (always a must to have them for safety reasons, despite considerable regenerative braking ability) and caliper complete the unit’s housing on the in-board side but isn’t sealed in to ensure the best cooling.

The Defender we’re driving is originally a 2005 model, and features a 75kWh battery pack. Each of the car’s four in-wheel motors are rated to 90kW (121bhp), and what BEDEO describe as ‘continuous’ torque is up to 479lb ft per e-motor. The conversion allows either 22kW AC or up to 50kW DC charging (via a neatly-incorporated CCS socket where the fuel cap used to be) and the team say they’ve managed to glean 153 miles out of a single charge. As for performance, a 0-62mph sprint is done with in around 10 seconds, and the Defender tops out at 81mph.

What’s the interior like?

The overall structure and design is classic Defender through and through. There are some tweaks and updates, but they’re designed to impede on the standard car’s feel as little as possible. The seats have been reupholstered, a battery charge meter replaces the fuel gauge, a new rear-view mirror incorporates info like a power meter and the shifter usually found on the centre console has been replaced by D, N and R buttons on the dashboard, as well as an ‘Eco’ mode.

A very retro steering wheel, petite seats and a chunky dashboard all feature. You sit imperiously high up, as always, and there’s barely any room for your elbow against the skinny doors. Again – a Defender specialty.

What’s it like to drive?

Turn a physical key, drop the handbrake and poke ‘D’ and you’re away, with the pedestrian safety hum that EVs are meant to have being the same one that Stellantis uses for its current electrified models – funny, that.

Acceleration is smooth and potent enough. This isn’t some Model 3 Performance here, but there is definitely more power than what you’d experience from some clattery Td5 diesel. And, because there’s no gearbox involved, it just progresses. The power available is tuned neatly and arguably gives a classic Defender a new lease of life.

Naturally, there are some Defender-based vagueries – the steering is woolly and takes a little getting used to compared to sharply power-assisted modern cars, and the brake pedal itself is a little spongey, for example. The biggest improvement is the noise. At lower speeds, that lack of clattering diesel engine vastly improves the interior ambience and even allows you to have successful conversations with your passengers. Zipping around town is easy and comfortable, and most of the noise at higher speeds is based on the Defender’s Lego brick aerodynamics.

Going off the beaten path in true Defender style down some green lanes proves the perennial Land Rover hasn’t lost any of its off-road ability. In fact, we’d argue that changing to an electrified powertrain has made going off road in a Defender even simpler. There are no ker-thunk-ing of levers, engaging of differential locks or even just feeding in power via a traditionally sluggish gearbox – the BEDEO Defender just glides over rough terrain. Given there are no gears to get in the way, getting yourself out of, you simply adjust your position and acceleration with the throttle alone, with our bumpy, rutted and very muddy green-laning dealt with as if it was a clean bit of tarmac.

Before you buy

Electric conversions for classic cars are getting more common, but this Reborn Electric Defender offers technology and engineering not really seen in the commercial market. While specific pricing isn’t public, the conversion certainly won’t be cheap – even if Whitehead and the team say their conversion is cheaper than going to some other specialists, or even JLR’s own Classic department.

BEDEO’s strategy is also not to sell the technology direct. If you have a classic Defender that you want converting to electric using this in-wheel motor technology, you need to approach the likes of Overfinch or Twisted and then they get in touch with BEDEO. Whitehead tells us that plan keeps its direct customers to a minimum and leaves other parts of the conversion (interior refreshes, new bodywork and wheels etc.) to the experts.

And, I hear you shouting: ‘but what about unsprung mass?’ Yes, this is a very good point – naturally including e-motors directly onto the wheels are likely to increase the amount of weight that can’t be adeptly by the car’s structure – something that the team have been aware of since the start. But BEDEO and Protean Electric are armed with a defence, with Whitehead pointing out that Protean commissioned a study that included Lotus Engineering. The study concluded that yes, including in-wheel motors do add extra weight, but having a motor on each wheel meant better stability and grip due to torque vectoring and individual wheel control.

‘We add typically about 35kg per corner,’ Whitehead tells us, ‘but what really matters is the ratio between sprung and unsprung mass. If you look at all the vehicles on sale today, the limits of the ratio are 5:1 to 9:1 – with most models sitting between six and eight. Provided that when you add unsprung mass, you keep it within that ration limit, you can still make a vehicle perform how it should. When we are adding our motors to these vehicles, we might go from 7.8:1 to 6.7:1, and we’re working on improving that ratio.’

Verdict: BEDEO Defender

It’s an interesting step in the use of in-wheel motors. While BEDEO and Protean’s technology is still in its commercial infancy, angling its use towards converting classic cars seems like a smart move to move the game on.

And the result in a finished conversion is smooth, sweet and adds some flexibility to a relatively inflexible classic. Electrifying a classic Defender frees it from a clattery and emission-heavy diesel engine, improves its overall performance and makes it a more refined thing than it ever was out of the factory. Given that was the aim, we’d call that job done.