► Renault sustainability goes into overdrive

► How new Scenic E-Tech can be recycled

► Reduce, reuse, recycle: taken to next level

A common criticism levelled at electric cars questions their true sustainability. They might have zero tailpipe emissions and whirr around in stately silence, but what about all the other stuff? The fossil-sourced energy when they plug in, the precious metals in the battery and carbon-intensive factories chomping through steel and plastic and goodness knows what else to build them in the first place… Wouldn’t we be better off never buying another car, servicing what we have and saving a fortune – and the planet – in the process?

It’s a conundrum that’s driving the sustainability agenda across the automotive industry and Renault this autumn presented an answer: the new Scenic E-Tech, its most sustainable electric family car yet. Twenty-seven years after the original first spawned the midi-MPV craze, the same nameplate has been slapped on an electric family SUV.

Renault sustainability: the next frontier

What caught our eye at its world debut this autumn was the claims made for the circularity of its production. Nearly a quarter of its materials are recycled and 90% of its mass is recyclable at the end of life, meeting the strict standards enshrined in European directive 2005/64/EC.

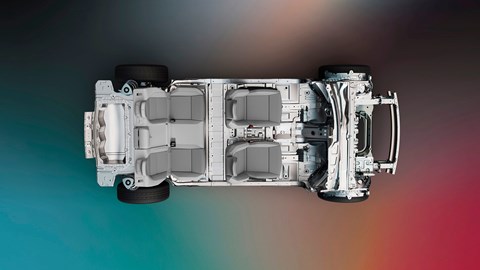

If the circular economy is becoming more relevant as we all consider our consumption habits, it seems Renault’s new family EV is especially keen to lighten its environmental impact. Crucially, that 90% recyclability figure includes the 87kWh nickel, manganese, cobalt (NMC) battery made by LG that’s nestled deep in the innards of the group’s latest CMF-EV platform.

Renault has committed to be net zero in CO2 by 2040 in Europe, and worldwide by 2050. It’s an holistic approach that’s spawned the Refactory facility in Flins – the group’s skunkworks for driving down its carbon footprint, reimagining new ways of giving its vehicles a second life and dismantling end-of-life cars. ‘It’s truly cradle-to-grave,’ vows Gilles Le Borgne, Renault’s vice president of group engineering.

The French car maker started using recycled materials in production back in 1993, so it’s hardly a new idea – but reused materials are fast becoming the norm, rather than the exception. An impressive 37% of metals on the Scenic are second-life while the bonnet and doors are 80% aluminium, reusing off-cuts from the production process.

‘We are looking at reusing second-fusion aluminium for safety parts like axles and so on, which is not the case today,’ adds Le Borgne. ‘The problem is the recycled parts can be too brittle, so we have to refine the alloy. It’s strange because the industry moved to high-grade, high-strength steel, but now we are going back to reusing conventional steel from H2 furnaces because it’s easier to recycle.’

The circular car is coming, eventually

This mantra of reduce, reuse, recycle has shaped the new Scenic E-Tech. An impressive 80% of the dashboard is made from second-life materials and the instrument cowls are 43% made of kenaf, a plant similar to jute. ‘Fabrics are one of the candidates to remove from our cars,’ the engineering chief reveals. ‘We have a lot of them.’ Hence why leather is banished from the new EV, the floor mats are made from recycled plastic bottles and the steering wheel is coated in bio-sourced ricin and cotton weft.

The challenge is twofold: as well as using more sustainable materials in production at the Douai factory in France, the engineers are also charged with making the new Scenic easier to dismantle, or upgrade, at the end of life. Ninety percent of the new model can be recycled and the brainiacs at HQ are working out how to increase that figure to make future models wholly circular.

Even the giant sunroof, dubbed the Solarbay panoramic glass roof (below), uses 50% automotive glass waste and nearly all of it can be recycled when it reaches the end of the road.

‘The last percentage points will be hard,’ admits Le Borgne. ‘The last 10% includes thermoset parts that are harder to recycle – they go to powder. All the glue, all the forming materials, it is very difficult. You have different areas where the process or technology does not yet exist to reuse them. Tyres are a problem, for instance: they are very difficult to reuse as is.’

So making that last 10 per cent recyclable will be hard miles, but Renault knows it has to do it. ‘Cost can be a problem, but recycling is like diversity. We know it’s the right thing to do and as a company we know we need to achieve it.’

Back at the dawn of the original Scenic its name stood for Safety Concept Embodied in a New Innovative Car. Perhaps today that should be updated to become Sustainable Construction Excellence in a New Intelligent Crossover.