► New power converter tech being researched

► Billed as ‘cylinder deactivation for batteries’

► Tech could improve range, EV design and enable solar bodywork

‘Cylinder deactivation for batteries.’ That’s how a new innovation in power converter technology is being billed as by Mercedes-Benz engineers working on the future development of EVs.

Mayk Stelter, an engineer for Mercedes-Benz, is among a team of future thinkers investigating what could be part of the next generation of electric powertrains. Stelter’s recent focus has been battery cell management, and how power converters work within a battery pack.

‘You have several power converters in a car. Five control the car’s sensors, 12 are for the radio system and four are for the car’s EV powertrain,’ says Stelter (pictured below). ‘But a lot of them are made of very conventional technology, and almost entirely hardware-based.

‘We’d like to introduce a new software-based one. One that uses not only the magnetic field [like a conventional converter] but the electric field as well, where the transfer of energy won’t happen via an iron core and copper winding, but in a system in the near-field area with a higher frequency.’

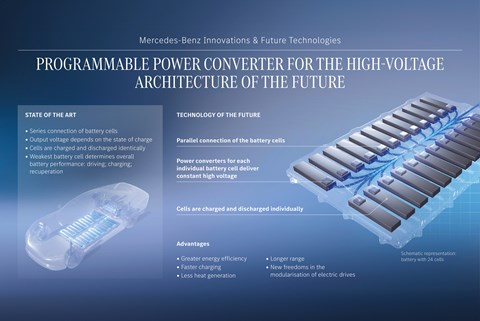

Stelter points out that there is usually just one conventional power converter serving an electric car’s whole battery pack, with all the battery’s cell sets part of the same circuit. While simpler, Stelter points out that power management this way means the whole battery is only as good as its weakest cell pack; if one cell pack is at a lower state of charge than the rest, that means the power converter reports that as the state of charge for the whole battery.

Applying a much smaller, software-led power converter to each cell pack allows much more control over the battery. ‘When you apply this technology, theoretically you can drive with one cell, even if it’s not very far for very long,’ says Stelter. But the bigger applications mean that more range could be extracted from a more acutely-managed battery pack, and there could even be a mix of chemistries applied for different driving situations. It also means that a constant voltage can be applied, even as a cell’s state of charge starts to deplete.

‘It’s kind of like cylinder deactivation 2.0.’ Stelter smiles. ‘With this we can run different cells in parallel, and we don’t care about the chemistry anymore,’ he adds, pointing to the fact that higher-density cells can be used for high-power or long-distance driving, while less dense ones could be activated for urban or slower driving situations.

Battery packaging is seen as another benefit, too. ‘We can split batteries where you have high performance batteries under the seat for more space, and little round cells under your feet where there’s less space,’ says Stelter. ‘That means the design of a car can change, because the cells don’t have to be all in one flat pack under the floor.’

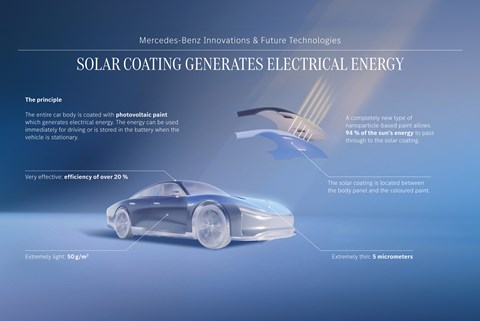

This tech also enables another innovation Mercedes is working on: bodywork with solar cells built in. Engineer Niels Schreuders (pictured above) points to the EQXX concept car featuring solar cells on its roof. Those cells initially worked with one power converter, but this innovation in a software-based converter enabled more solar energy to be extracted from the roof-mounted cells.

‘The power converter technology is an enable for this to work,’ says Schreuders. ‘With EQXX, the solar roof accounted for 30km of extra range – all of the energy in there helped the car go 30km further.’

The next step is what Mercedes calls ‘solar coating’ – literally covering the bodywork of the car in flexible solar cells that don’t shatter under high tensile loads like conventional ones do. ‘We can apply the solar coating to any material,’ says Schreuders as he holds a new-generation solar cell on a panel of metal, ‘as it can bend and be thrown around and I won’t be able to break it.’

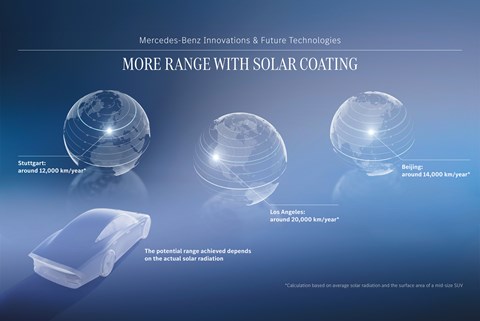

And this is where Mercedes’ engineers have made some calculations for if an entire car’s bodywork was solar coated. On a mid-size SUV, like an EQE SUV, Mercedes predicts you could add around 7500 miles of range to your car per year if you live in Stuttgart; 8700 miles per year in Shanghai or 12,000 miles per year in Los Angeles – provided you keep your car clean.

The power converter technology feels extremely tangible, as if it could make its way to the next generation of Mercedes-Benz EVs – likely within the next five years. Stelter believes this won’t add extra weight or cost, as the simplification of other components would outweigh (monetarily, and literally) the inclusion of more power converters. ‘I think the advantages of using this kind of power converter are much bigger and will, in the end, save the market money.’

The ‘solar coating’? That could take longer, as there are quite a few complications when it comes to productionising this technology. Even so, knowing that engineers are working on it means a solar-powered car that isn’t impractical or seen as experimental won’t be science fiction much longer.