► The latest tech intel on Neue Klasse

► BMW unveils new electric powertrains

► First car to benefit is new iX3

BMW has just pulled the covers off its next-gen electric powertrains recently, as it gears up to deliver the first of its Neue Klasse cars, the iX3, later this year. But the broader plan hasn’t changed. And as world goes to hell in a hand cart, that powertrain plan – i.e.: to develop EVs as well as combustion models and do it mostly in-house – is looking increasingly prescient.

‘We retain our technology-open approach [i.e.: offer all powertrain options and let buyers choose] and our philosophy is the same: production follows the markets, and the supply chain follows the production,’ explains BMW’s Dr Joachim Post, purchasing and supplier network member for the board.

But there can be no doubt, either, of the potential for growth if BMW can so something special with this next electric era. Its aware of this, hence the reprisal of the Neue Klasse descriptor. Back then, the original Neue Klasse cars transformed BMW from bit-part player to premium powerhouse. The challenge now? To become synonymous with EV powertrain excellence in the same way it did with great engines. After all, you can count the number of manufacturers with a headquarters that’s also a monument to the four-cylinder engine on the fingers of one finger…

A lighter, more efficient and more energy-dense modular toolkit, BMW humbly describes Gen6 as a ‘quantum leap’, as you’d hope given it’ll go into the first electric BMW to wear a proper M badge.

The headline claims for the new 800-volt battery technology, which switches from prismatic-type cells to a 46mm lithium-ion cylinders in two lengths (95mm and 120mm) are faster charging (by 30 per cent), a 30 per cent increase in range (with some future models going further still), a 20 per cent increase in overall vehicle efficiency and a massive 40-50 per cent cost reduction versus a comparable Gen5 powertrain.

A step-change, then, though some of that progress will go into BMW catching up rather than stretching ahead. Though powerful, the Gen5 kit isn’t the most efficient when compared with some rivals. An i4 M50 we tested in 2023 averaged 2.2 miles per kWh. Across the same roads on the same day, a Model 3 and Ioniq 6 managed 4.8 and 4.2 respectively. More recently, our long-term i5 eDrive 40 has averaged an underwhelming 2.7 miles per kWh.

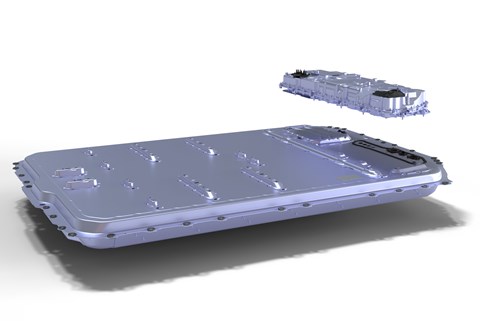

It’s claimed Gen6 also delivers gains in terms of packaging efficiency. The new battery is flatter than before, making it compatible even with low-slung M cars, and is more efficient by design, with no internal modules thanks to its direct, ‘cell-to-pack’ construction. Versus Gen5 packs, the battery’s external mountings are far simpler and lighter, too, and the Neue Klasse cars will use the battery as a stressed member.

BMW isn’t making its own cells, naturally, but it is doing virtually everything else in-house. A further five battery production facilities are in the works (five existing plants build the Gen5 batteries), in Bavaria, Hungary, China, Mexico and the US. The Group plant at Landshut is gearing up to produce sufficient ‘Energy Master’ control units (which was developed entirely in-house) to supply those plants, and on the motor side BMW’s Steyr plant is being modified (as part of a cool 1-billion-euro investment) to be able to churn out 600,000 motor units per year. Steyr will also produce the inverters, while the motor casings are being cast at Landshut.

Just as different engine architectures better suit different applications, so BMW’s using a mixed approach, with more expensive, high-performance EESM (electrically excited synchronous motor) units on the rear axle and more cost-effective and compact ASM (asynchronous motor) units on the front. In terms of outputs, BMW’s rating the 120kg rear units at 197bhp to 296bhp and the 70kg fronts at 118bhp to 178bhp.

Its long been a fan of EESMs for their sustainability (no rare earth metals). It also reckons they’re efficient under part load and powerful at speed. The new units contain a bunch of patented tech and promise quieter and smoother running, a lighter and more rigid housing, big power and torque and reduced losses. As before, they’re self-contained units that bundle together the motor, transmission and the inverter (now silicon carbide; more difficult to make but more efficient).

So far, we know Gen6 BMWs will use an EESM motor module on the rear axle and the ASM unit up front, for all-wheel drive, but it has confirmed the Gen6 toolkit can be used to create cars with three or even four e-motors. Though it’s reluctant to discuss about other combinations, two-wheel drive Gen6 cars will likely be rear-wheel drive: ‘It’s in our genes,’ explains Michael Salmansberger, head of electric drive. ‘At BMW we all like the rear-wheel-drive feeling.’ And the fact that BMW’s been running a circa 1300bhp, quad-motor electric M3 prototype for while would suggest M cars will use the more high-performance EESM units on both axles.

With a 50 per cent reduction in production costs on the batteries and 20 per cent on its motor units, does Gen6 promise price parity with piston-engined BMWs? ‘You are successful only if you have the right price for the customer, but you also have to be profitable,’ explains Dr Joachim Post. ‘We must balance these things, and despite the huge cost reduction with Gen6, costs are still the main challenge with electric cars.’

We’ll take that as a maybe.

More certain is a new era of performance. Talk to M boss Frank van Meel and he’s always at pains to point out that M is totally embedded within BMW, not merely a tuning shop for its output. As such the division’s involvement in new-platform development begins at the beginning and doesn’t let up: a little more stiffness here, bitte; the scope for a wider track there…

‘When we develop a new technology, we’re always thinking about it from the entry level of the core models right to the high end, and that’s M from a performance perspective,’ confirms Post. ‘M’s requirements are factored in early, so we can get the technology right and scale it for our whole range.’

‘Frank was not annoying at all,’ smiles Roland Welzmüller, vice president of electric engine technology. ‘M was involved from the very first moment. As you know, right now we have no pure M car in our EV portfolio, and for this new generation we are planning to have M inside this portfolio. So from the very first day of this strategy it was involved, and we have found dedicated solitons for M which we will tell you more about when the time is right. Let me say though that {in terms of power-to-weight ratio] there is no compromise – it will be a real M car. If you are coming from today’s M3, and you are thinking about a fully electric M3, customers do not want to have a limitation.’