► Heart of Joy black box in Neue Klasse

► Does away with multiple ECUs

► A quicker digital brain = better performance

BMW’s IAA motor show was clearly focused on the Neue Klasse concept, but the Munich brand also revealed an important piece of tech that’ll feature in every BMW EV in the future. Called rather cheesily Heart of Joy, it’s an all-new single software hardware stack that promises to bring the brand’s historical ultimate driving pleasure to a new age.

Heart of Joy is the first time BMW has ever combined the powertrain software (engine) and driving dynamics (handling) in one unified system, bosses claim.

Masterminded by BMW’s SVP of driving experience Dr Nicolai Martin and his team of ‘experience makers,’ it’s going to be a cornerstone of Munich’s future EV offering and is designed to speed up the car’s digital decision making.

BMW Heart of Joy: a Steve Jobs moment at the IAA?

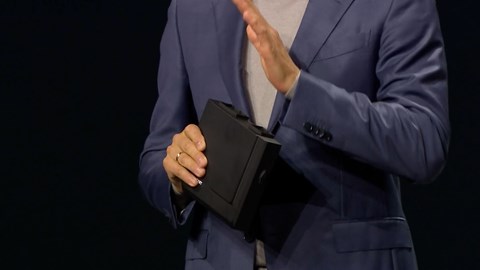

After the wraps came off the Neue Klasse at the 2023 Munich motor show, BMW CEO Oliver Zipse briefly mentioned the new tech on stage and held up a small unassuming black box around the size of an external CD-Rom drive (remember those?).

‘This is a revolutionary combination of hardware and software,’ he told reporters. ‘For the first time we are merging both – the powertrain software and the driving dynamics software in one control unit. It’s an electronic super-brain of the car: super-fast, super-precise and of course super-smart. Our engineers internally call it “Heart of Joy”.’

It is a ‘one more thing’ moment Steve Jobs would have been proud of. And like Apple products, the Heart of Joy isn’t just hardware, it’s just as much about the software.

What does it do?

Rather than one centralised ‘brain,’ cars tend to use a collection of smaller ECUs to manage functions such as braking, traction control and other dynamics – but BMW’s system gathers all those functions into one inhouse developed central brain. And it means that, much like Apple, BMW does both the hardware and the software.

‘We have one central software stack, and we call it the ultimate driving stack,’ says Martin. ‘It’s fully owned and developed by BMW.’

Munich is finding it’s harder to differentiate the performance of EVs compared to combustions cars – and there was a need to make electric BMWs feel unlike anything else on the market. In the age of electrification BMW must double down on ‘sheer driving pleasure,’ and this is the tech to do it.

By keeping everything within Munich’s city walls, BMW’s engineers have been able to prototype and refine their system without external delays – in effect they’re now developing like a startup or F1 team. ‘It speeds us up like a racing team on the test track to develop,’ Martin tells us.

What are the benefits?

Having separate ECUs increases the lag time for most functions, as the signal must effectively pinball to multiple black boxes before the car can physically do something. In contrast, BMW’s centralised system has a smaller delay, because all the sensors and functions are within the same stack.

‘The ECUs have a time lag to interact,’ Martin says of conventionally managed cars. ‘If you have different ECUs on a bus system in the vehicle for braking or for powertrain – you will have at least 10 milliseconds or 20 milliseconds interaction time in the cycle. If we bring that all together in one software stack, we have an interaction time of only one millisecond.’

Having a system that can operate 10 times faster comes with huge benefits, especially in performance. ‘When it comes to driving dynamics on racetrack or real dynamic driving on rural roads, it’s totally different,’ claims the software engineer.

A lack of delay means each aspect of the car’s performance can react more quickly and more intelligently, thereby creating a more analogue feel than traditional systems. Traction control can react quicker and in a less obvious manner, for example, and the overall result could be something that’s less intrusive than contemporary systems. Significantly, this is something that simply couldn’t be done on ICE vehicles – only EVs allow such close control of each axle, let alone each wheel.

Still, even with these new possibilities, developing the Heart of Hoy hasn’t been easy. It’s been in production for two years – with a further two until it’s released in the first Neue Klasse: ‘If you drive a current i4 M50, it behaves quite well,’ Martin says. ‘It’s challenging to come with such a new technical approach, first to match the same level and then to go beyond that.’

While the Heart of Joy promises to add sheer driving pleasure, it could have other more mundane benefits. Martin explains that the system is quicker and more intelligent when it comes to using the e-machine or physical brakes for slowing down for example, thereby saving a little more electricity than current systems.

All those small efficiency gains add up when you’re making an electric vehicle.

Sheer driving pleasure remapped for the EV era

Like other manufacturers, BMW is preparing for the electric age by doubling down on its heritage and key brand promises. The Neue Klasse already has the styling of classic BMWs, but Munich hopes its new software/hardware solution means it’ll generate the same driving experiences too.

We’ll be able to test the Heart of Joy in production form in two years’ time.