► Richard Parry-Jones obituary – and interview

► Engineer who made Fords great to drive

► We look at his influence and legacy

The Ford engineering great Richard Parry-Jones has died after suffering a heart attack on his farm in Wales. He is the executive credited with making modern Fords handle and drive so well, starting with the 1990s Ford Mondeo, Ka and Focus.

Scroll down to one of his last interviews with our former sister magazine Modern Classics, where he explains the back story to the Ford Focus.

His focus on dynamics drove an industry-wide seachange, promoting the finer points of ride quality, more expensive suspension components and performance that percolated every modern Ford around the turn of the century – and further afield. The team that developed the Volkswagen Golf Mk5 was staffed by ex-Blue Oval engineers, for example, as Wolfsburg poached engineering talents from the influential 1998 Focus Mk1.

Welshman Parry-Jones’s passion for making even quite humble cars good to drive was driven by the lows plumbed by earlier Ford products, especially the mediocre Escort which was panned by this magazine and many others.

CAR Magazine joins the rest of the motoring industry in paying homage to an engineering great. Our sister title Modern Classics had the privilege of interviewing him about the inception of arguably his finest car – the Focus – and you’ll find that interview below.

How Richard Parry-Jones’s dynamic focus reinvented modern Fords

Stung by criciticism in the media, Ford embarked on a mission to make its mainstream cars class-leading and the first fruits of its labours was the 1993 Mondeo, which represented a turning point for the company’s family cars.

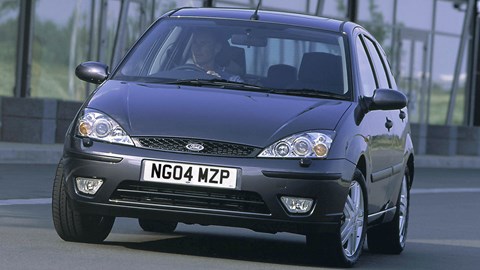

But it is perhaps the 1998 Focus that will be best remembered. This was a car that so comprehensively ripped up the rulebook that CAR hailed it a modern masterpiece. It might have been the futuristic New Edge styling that caught the eye, but it was the razor-sharp dynamics and expensive multi-link rear suspension that blew away the bitter memories of how bad its Escort predecessor had become.

As well as leading Ford’s 30,000 engineering staff globally, Parry-Jones also headed up the group’s ill-advised F1 efforts in the early noughties; he’s pictured above alongside Sir Jackie Stewart during a Ford and Jaguar Racing media briefing to announce Niki Lauda was relinquishing his role as manager of Jaguar Racing.

Parry-Jones left Ford in 2007 to pursue a life in consultancy. He continued to sit on many advisory boards and government bodies, helping shape the UK’s automotive industry.

Blue Oval chairman Bill Ford led tributes to Parry-Jones: ‘He was a rare talent who left an indelible mark on Ford and the industry. As an engineer, he was a virtuoso with an uncanny feel for creating cars that were dynamic and incredibly fun to drive. I can tell you that going on a test drive with him was not for the faint of heart.

‘His passion for great cars and love of motoring inspired legions of engineers and enthusiasts in Europe and around the world. Richard will be deeply missed and our heart goes out to his family and loved ones.’

The generation of engineers coached by Parry-Jones

Parry-Jones’s philosophy of bringing brilliance to everyday cars has spread throughout the industry, led by proteges such as Ulrich Eichhorn (who went on to do great work with VW and Bentley) and Matthias Tonn, the engineer who made the new Ford Mustang Mach-E drive so well.

Tonn told CAR: ‘I first met Richard in 2001, at a design review for the new C-Max. When Richard was in the room, he had an aura. You paid attention. My next contact was two years later when I was chief programme engineer for the new Focus ST. The Focus was the new era of Ford. Richard was always about the chassis, steering, brakes and shifting. He was very much into shifting. Twenty or 30 years back, good shifting and precise steering was rare in a normal car. The ST 170 was the first chance we had to bring in a transmission and a steering that was superb.

‘He really transformed Ford into a car company with a reputation for great driving cars. He could translate a customer’s perspective into engineering, into what this car should or should not do.’ That meant analysing what customers wanted from a car – great steering and gearshift in a Focus ST, but safety and confidence in a Ka, for instance.

‘Richard spoke about craftsmanship. What you smell, see and feel, the customer experience. You as a customer may not know about steering precision or brake undulation, but you know there is a stop light and you want to stop there with high confidence. Same with good steering – you don’t want to end up in the ditch. Compared to the RS fanatics, he knew where to draw the line. We had people talking about a Ka ST or Ka RS, but he knew when to say no.’

Tonn spent a decade learning from Parry-Jones. So he was delighted when the VP told him how much he liked 2010’s Focus RS500, which applied many RPJ principles: ‘That was great, the pinnacle of work we’d done.’

What would he have made of Ford’s move into EVs? He certainly had an interest in green matters, and was focused on everyday cars rather than supercars.

‘Clearly he was not the one thrilling at V8 engines all day long,’ said Tonn. ‘It was not just big engines and sheer horsepower. I would love to have had a discussion with Richard on the Mach-E, on what needs to be done to make it superior. What do we do with the Mach-E GT that’s coming in the autumn? What do we do about the next generation?’

Parry-Jones’s thinking is widespread among engineers, not just those who worked with him for years at Ford. For instance, Louis Kerr, lead dynamics engineer on the Lotus Evija, has been using the RPJ ’50-metre test’, where within the first 50 metres of driving a car you can feel the immediacy of the steering response and the connection to the road.

His work on road cars was always informed by his long invovlement with rallying. Parry-Jones’s long-term friend Nicky Grist, co-driver for Colin McRae in the Ford Focus WRC, said: ‘He’s always had this love of cars. Through rallying, where performance and car handling became so important, that’s where the engineer in Richard really came through. Making a car handle was what it was all about.

‘When the Ford Focus came out, all of a sudden you’ve got these underpowered cars doing extraordinary things. Compared to the Cortinas of the ’70s and early ’80s, you’ve got far less power but so much extra speed, all through handling, and that’s where Richard transformed the brand.’

Even when he was based in Germany and the US, he stayed in touch with his rallying mates.

‘Richard was always much interested in what was going on with the car – why have you engineered it like that, what’s going on with the traction control systems? His passion for engineering shone through. [M-Sport boss] Malcolm Wilson – running Colin McRae and myself at the time – was often on the phone to him, talking through engineering problems,’ Grist told CAR.

This marked him out as very different from other executives. But his continuing interest in engineering was on top of his boardroom role, not instead of.

‘He was also a formidable man in negotiation – you don’t climb to such heights in a large corporation if you can’t hold your own among these high-flying indiviudals. He was able to stand his ground.

‘When you get to the board level, there’s a lot of talking goes on. When you find someone who can talk and do at the same time, Richard was at the forefront of that,’ said Grist. ‘His legacy will live on. He leaves behind his experience and his knowledge will live on in the young engineers coming into the car business.’

The Focus I created: an archive interview with Modern Classics

Richard Parry-Jones reveals how the lessons learned during the Mondeo project went on to make the Focus so great

The man responsible for the Focus very nearly wasn’t… ‘I was all packed and ready to run a factory in Valencia,’ says Richard Parry-Jones. ‘I had the house and children’s school sorted, and then I got a phone call. “We want you to go back to research and development and take over vehicle engineering,” they said. “We’re in trouble.’”

For RPJ, the call was irresistible. After all, he is Blue Oval through and through – he started as an undergraduate trainee engineer in 1969, and swiftly rose through the Ford ranks to run the Cologne plant. He’d played an important part in the game-changing MkIII Escort and Sierra. Ford, reeling in the wake of the calamitous Escort MkV launch, needed his help.

And boy did they need him. The Escort MkV had been a disaster, one born out of an old-school mentality, according to Richard. ‘I’d worked for Ford for 20 years and for most of that time, the company was really good at selling to fleets, and didn’t really sell to retail buyers – hence the focus on costs. As such, there wasn’t much about it the user actually wanted,’ he explains. But big changes were afoot – the Japanese and French had become wise to the profit margins possible in the UK market. More retail customers were entering showrooms, and with more choice in car fleets, Ford’s profits had plummeted. The mediocre Escort MkV really didn’t help.

Its frosty reception truly shocked Ford senior management. Worse still, its critical Sierra replacement, the Mondeo ‘world car’, was in trouble too. ‘It was just a bit mishandled,’ says Richard. ‘I found that many targets for stiffness and so on had been set, but not enforced. I began to ask what was needed to fix it.’

Richard never accepts the answer that it can’t be done. ‘The only question is how can we do it? It might take too much time, or too much money, or it might take both. But give me some options – don’t say it can’t be done, show me how it can be done,’ he says. ‘This approach is quite refreshing for engineers. It’s amazing how, once you start that conversation, how inventive people can become. Then they actually start having fun!’

It still took time – there were plenty of six-hour meetings to sit through. ‘I was chief engineer and I knew I couldn’t really do this – but I had to. I had to train and teach them the skills, and set standards they’d lost or forgotten over many years.’

He quickly sought to change the company’s entire philosophy. ‘We needed to make these cars appealing to ordinary retail buyers, not just fleets. They must be something people desired and then really enjoyed owning – a fundamental change. I had a lot of people fighting me, but there were also a lot of people hurting from the Escort launch and wanted a change.’

With RPJ steering it, the Mondeo turned into a great success. And this, along with the successful launches of the Puma and Ka gave him the clout he needed to make the Focus the way he wanted.

The critical part of the Focus, and the chief reason why it handles so well, is the Control Blade rear suspension. However, its inclusion wasn’t all plain sailing. ‘If you’re convinced about something, you have to fight for it. I had all the data, and I was sure we could deliver ride comfort, good NVH (noise, vibration and harshness), steering and handling that no other manufacturer with twist beam suspension could do. Even so, it cost an extra 50 dollars per car.’ That might not be a problem for a premium brand, but for Ford, and its public perception, it was a tricky sell.

‘Will people pay extra for that? No, they won’t – not immediately. But they might buy the car and recommend it to their friends,’ he explains. ‘It’s an investment, really. When it came to the crunch, the management backed me, and for that I’m grateful. More importantly, I think all the customers were grateful too.’

Richard believes it’s much easier to build an exotic car than a mainstream one. ‘In a mass-market car you have so many cost constraints – you have to be innovative without using exotic parts. All the special bits in the Focus are mild stamped steel – nothing fancy. It’s all about trying to find the performance you want, using physics to analyse carefully and to synthesise a simple solution.’

That plays into Richard’s wider philosophy. ‘The simplest design is the best design. You have to factor in a certain amount of feeling, of soul, of taste – you can’t do everything by the numbers,’ Richard admits. ‘But if you get the numbers right first to avoid making basic mistakes in the design, you buy yourself the freedom to perfect the product, not spend all your time fixing problems.’

Getting the Focus design right was the biggest early challenge. Design trends pointed towards family cars imbued with sporty styling – Richard cites the Mazda 323F. There was another trend appearing – taller cars, such as the Fiat Panda. ‘People are getting taller and heavier, and they need more space,’ Richard says.

Most of the early sketches were low-slung, Mazda-style designs. One, from a UK stylist, caused him to stop and think – it added around 60mm to the height of the car. ‘It was taller, but not by much,’ he says. ‘For the same length, we got a lot more interior space. I asked the designers to do a study based on this.’

At the time there was a big push within Ford for a bustle-back design, something the Escort was famous for. ‘Even the 323F is a bustle-back,’ says Richard. But when the designers returned with their work, Richard wasn’t pleased. ‘It looked like a Mazda 121! It looked like a Noddy Car. We had to go to a hatchback.’

Still Richard wasn’t happy. ‘It all looked predictable. I wanted to go into the studio each week and be wowed, and it wasn’t happening. We were running out of time.’

The pressure was on. The team knew they had a good package. The aero was looking very good, too. ‘But the design looked ordinary. Then a young designer showed me a sketch that was interesting, and two weeks later I came back to a clay model. This was the first time we’d put the headlamp high, and we blended it with the window line. It was new and dynamic. I said: “Wow – you’ve found a way of making the car not look tall.” I thought, my God, I like this. Then we sent it out to research.’

Richard knew the Focus would be polarising – but that was a good thing. ‘The winner is not the car that scores the best. You have to look behind the data, look at people’s propensity to adopt change,’ he explains. ‘You show them other non-car items so you can map them to see if they’re leaders or followers in design. Find the people who’ll lead opinion, and favour those answers.’

Richard also spent a lot of time at customer clinics. ‘The finished design caused more than a third of respondents to stop and go “wow”. That’s when I knew it was the one.’

The interior was almost very different. ‘We had two themes in the final run-off. One was more symmetrical, more rectilinear, and the one in the finished car. What we have now matches the exterior’s swagger,’ Richard explains. ‘I think we got the broad brushstrokes OK, but I don’t think we got the calm cohesion of the German manufacturers. The interior might have been better if I hadn’t spent 50 dollars on the rear suspension…’

There were still challenges, however. During development, Volkswagen started offering 12-year corrosion guarantees – a big value enhancer. Ford needed to follow suit. ‘We found it wasn’t hard to implement, even though it came late in the car’s development.’

But every project has to end. ‘You can always find something to improve. In that way I’m a perfectionist,’ he says. ‘I’m also a pragmatist. I knew we had a car we could be proud of. So I said: “Let’s finish – it’s time to make sure not just the prototypes are great, but every car.”’

The team knew the car was good, but they weren’t prepared for the accolades it received. ‘We didn’t realise the journalists, the public and the competitors would say: “The game’s changed!” I’m told the Focus changed the way the entire industry engineered all cars for dynamics. Less so for NVH, but the framework where you had to have good dynamics OR good NVH was largely abandoned. That’s very satisfying.’

Making the project satisfying to work on was paramount. ‘Most of the people had helped design the Escort. The skill and passion was there, we just needed to harness it. The key was to use everybody’s knowledge and make them feel they were making a difference.’

The car was received well, and is the only car to win Car of The Year titles in North America and Europe. But what about sporty models? Magazines raved about the Focus in a way few mainstream cars had ever enjoyed before, but a sporty model was sorely missed. The ST170 finally reached showrooms in 2002. This might seem at odds with Richard’s history. After all, he was inspired to become an engineer by watching the RAC Rally, and his favourite company car was the Sierra RS500 Cosworth. He’s only recently given up rallying a Fiesta. So why the delay? ‘I had to make all the base cars really good, rather than settle for “that’ll do”, and let the hobbyist in me focus on the sporty models. I didn’t want to fall into the same trap my predecessors had done.’

The lack of suitable powertrains was also an issue. ‘Even with the ST170, we knew it didn’t have enough power, but it was the best we could do at the time.’

Despite that, Richard still has a fondness for the ST170. ‘It’s a lovely car to hustle along a great road. You can carry speed through every corner; you don’t need a lot of power as the handling and grip is so good, and the steering is uncorrupted.’ Richard was less involved in the RS – he’d moved on to America by then, but he concedes that it came to the product cycle far too late.

Nearly 25 years on since the project started, and 20 years since its launch, Richard looks back on that time fondly. ‘I was only 40 at the time, and to have the chance to do a car like that, and be trusted by the senior board and investors to spend about $3 billion was just amazing.’

Looking at the transformative effect the car had on the brand and market, that 50 bucks spent on extra pressed steel was well worth the investment. But it took persuasion to make it happen. And that’s the biggest part of how the Focus came to be so great.

‘There are three key pillars for persuasion. Do you have a compelling business framework? Do you have the scientific evidence, the data, which will support your argument? Then you have to show them how you’ll do it,’ he says. And the third pillar? ‘The boss may be looking at you and saying everything looks good on paper, but can I trust this person to deliver? You have to convince them you can do it,’ says Richard.