► CAR visits the world’s largest car engine factory

► Audi’s Hungary facility is in the middle of an electrification shift

► We ‘help’ build an electric motor explore inside

Audi’s factory in Gyor, Hungary is the largest engine factory in the world.

The plant is crucial to the brand and the VW Group – one that has, since 1993, produced more than 45 million engines and counting. It’s built everything from dinky three-cylinders to beefy diesel V6s, warbling five-cylinders and the Audi R8’s screaming V10.

Audi Hungaria (as it’s known) has also assembled all sorts of Audi models like the TT from 1998, the A3 and the Q3, and it manufactures body parts that go into Audi Sport models, Lamborghinis and Bentleys. More recently, it’s become the manufacturing home for the new Cupra Terramar. The plant is so large that it has become one of Hungary’s biggest employers and is its largest exporter.

More recently, though, the Gyor plant has found itself right at the centre of Audi’s and the VW Group’s shift towards electrification. ‘After the production of combustion engines, in recent years we have embarked on the path of e-transformation,’ Peter Will, member of the board for powertrain production at Audi Hungaria, tells CAR. ‘Our goal is to be a part of and a strong player in the transformation of Audi.’

The Gyor plant employs around 12,000 people. Around 5300 of those employees are in powertrain production, with around 2000 having retrained from manufacturing combustion engines to building e-motors. As well as building around 9440 combustion engines a day, Gyor produces 2550 electric motors per day – namely for Audi’s PPE platform cars like the Q6 e-Tron and A6 e-Tron, as well as the electric Porsche Macan.

It’s here we learn just how complicated building an e-motor is; the production process is arguably quite similar (and as complex) as manufacturing a combustion engine. In a permanent magnet electric motor used in the Q6 e-Tron, there are 226 ‘hairpins’ in the stator and 216 welding points. While e-motors are designed to use far fewer components than combustion engines, the myth that an electric car has ‘just one moving part’ is just that – a myth.

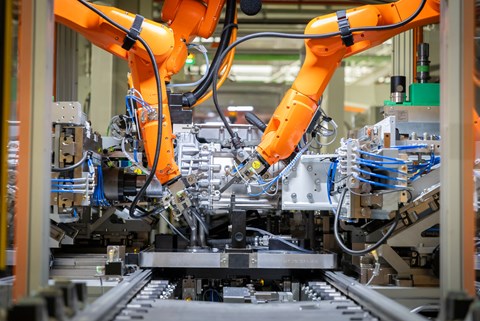

The e-motor plant works a lot like an engine factory does; units come down a line with each part being added one at a time in supremely efficient harmony, with each motor being tested for noise and vibration before it’s ever sent towards a car in the process of being built.

But, sometimes, human intervention is needed. A training centre features in the factory, designed to get employees up to speed on the parts that require them to be hands-on. We are guided through some of the process by the training team, led by Zoltán Erdödi – a ‘try-out’ engineer who works with employees on pre-series production projects to get them up to speed building new models or engines. We’re instructed to help install an oil pump and reservoir system into an electric motor for the Q6 e-Tron, including bolting in and sealing the unit. But you can rest easy – it’s just a training mule, and this electric motor won’t end up in a production car. I’m not sure I’d enjoy the impending lawsuit if it ever fell apart.

Back in the real world, though, that brand transformation and Group-wide shift has come with pitfalls, industrial lag and slumping consumer demand. So much so that it’s threatening Audi’s manufacturing structure in Europe. Its Brussels site that manufactures batteries and the Q8 e-Tron, for example, will likely have to be shut down as demand dries up and buyout offers from other companies haven’t materialised in the way Audi has wanted. Volkswagen, too, is facing similar threats to its factories in Germany.

Plus, only a week after we had visited the Gyor facility, Audi published its Q3 2024 results on 5 November. They’re not pretty, with large drops in operating profit and reductions in deliveries in Europe, the USA and China respectively – even if the company says it will return to better profitability with new model lines like A5 and A6 coming on stream.

In a response to shifting trends and wider competition, Audi has already announced a shaping up of its business at the top company level. The aim is to reduce management bloat and speed up the development of new models, with Will saying the Hungary facility has a big role to play. ‘We’re ready to support AG,’ he says, adding that the facility also provides a huge amount of technical development for the Group. ‘We have a real impact at an early stage [in the development of new models] through our technology centres here,’ adds Will (pictured below).

The Gyor plant’s strategy of working on different projects at once seems to be working. Slightly relaxed strategies regarding the pace of electrification and Audi’s renewed focus on its new, hyper-efficient ‘Premium Platform Combustion’ cars could see Hungary remain a crucial plant. That, and the fact that it’s not got all its eggs in the electrification basket – unlike the Brussels factory – has meant it’s seemingly not a target for layoffs or closures.

‘The e-mobility transition is not new to us,’ says Will. ‘The company started making electric motors in 2018 and, since then, more than 600,000 electric motors have been manufactured in Gyor. Series production of PPE drive units started in 2023, and the company is preparing for the next generation of e-drives.’

That next generation will be the units powering cars running on the SSP (Scalable Systems Platform) architecture, meaning Gyor’s place in the world seems secure. While the Audi brand and wider VW Group are experiencing a structural earthquake, Gyor seems to only be feeling light tremors.