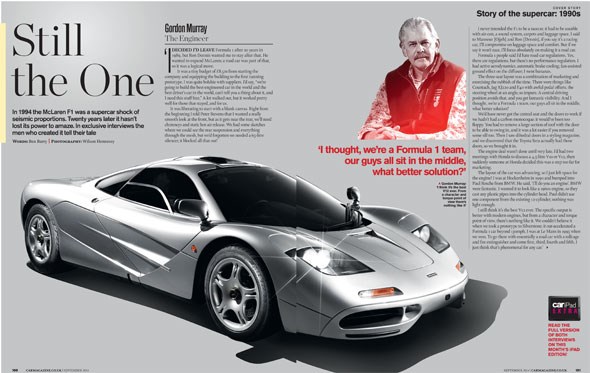

For a kid who grew up in the ’80s and ’90s with those cliché supercar posters on my wall, the chance to chat to Gordon Murray and Peter Stevens for the September 2014 issue of CAR magazine was both terrifying and incredibly exciting.

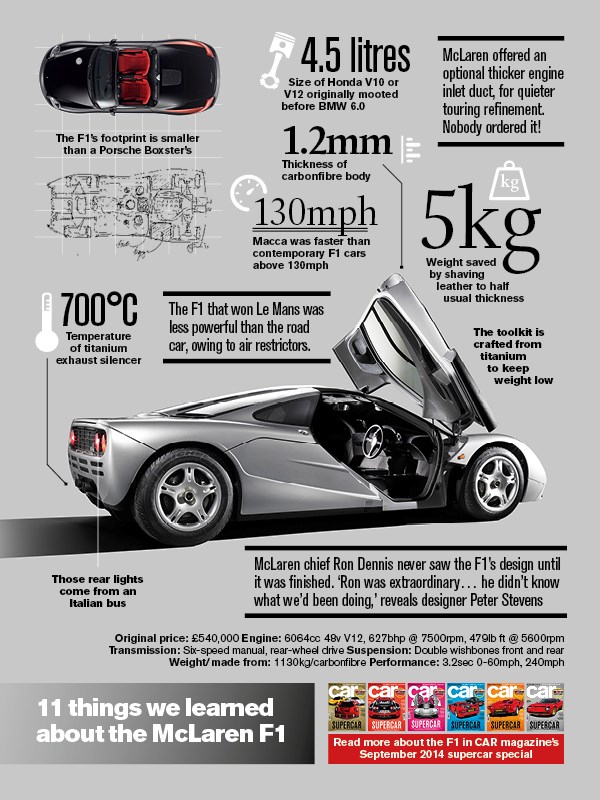

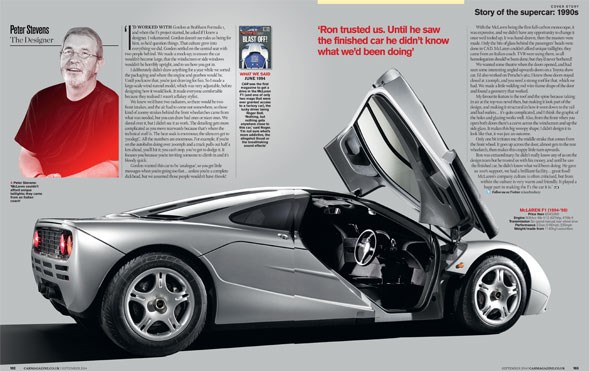

In the name of completeness I’ll mention that Murray was the genius behind the McLaren F1, designer Stevens a key player, but most of you won’t need to be reminded. You’ll know that Murray and Stevens, along with a small but brilliant team, created a supercar that beat Lamborghini and Ferrari and everyone else in the world.

My first thought when I was asked to pull together this story was, ‘ugh, I hope they’re not both just bored talking about it’, quickly followed by wondering how bored you’d be if I just banged on about the engine bay being gold-plated and Mr Bean having an off.

Luckily for me, both Murray and Stevens were generous with their time, happy to talk and full of facts and insights that I’d never before heard. You can find the edited interviews in the magazine (and a longer excerpt on our iPad edition), but there was such stuff that we couldn’t fit it all in. So, the list below includes 10 nuggets from two genuinely enjoyable and only slightly terrifying chats, but there’s plenty more to dig into in the magazine:

1. There’s Jaguar and Lotus DNA in the McLaren F1

Peter Stevens had worked at both Lotus and Jaguar immediately prior to joining the F1 programme; he’d contributed to both the stillborn Lotus supercar and super-rare – and, crucially, carbon-bodied – Jaguar XJR-15 road car. Other specialists from both companies also had an impact at McLaren. A young Steve Randall was responsible for the F1’s suspension. His dad was Jim Randall, the chief engineer at Jaguar. ‘Steve’s bleeding clever and the F1 suspension was exceptionally good,’ says Stevens. ‘Sometimes he had enormous tussles with Gordon. It’s quite healthy that that should happen, and Steve thoroughly enjoyed it; it really makes you get your ducks in a row when you argue with the boss.’ A homologation specialist also joined from Jaguar, getting the F1’s bus tail lights homologated for a car and ensuring the Nardi steering wheel met head-impact tests. Several Lotus employees jumped ship. Barry Lett was a body engineer who had worked on the stillborn Lotus supercar with Stevens, and also the Lotus Carlton. ‘Barry was hugely valuable,’ remembers Stevens. ‘He was enormously disciplined; he’d never just take one view when three views would make sure it was the right engineering direction. He understood that the thing had to stay together at more than 200mph, so we should be very sure that everything was strong enough.’ Mark Masters did the brakes on both the F1 and the Lotus Carlton, and Mark Roberts – a good friend of Stevens – moved from Lotus as a technical illustrator. He’s still at McLaren today.

2. There’s a Bernie Ecclestone twist to the story

If it wasn’t for Bernie Ecclestone, Stevens and Murray might never have worked together. Back in the 1970s, Ecclestone was team boss of Brabham F1, Murray the team’s design chief. Stevens had heard Brabham were getting a new sponsor – Parmalat – and so gave Ecclestone a call. ‘I said I’d like to do the graphics and Bernie said “be down here tomorrow morning”,’ remembers Stevens. ‘It was one of those fortunate, chance phone calls. I did all the graphics during Brabham’s Parmalat period and worked with Gordon for quite a few years, and eventually I got a bit of input into the modelling shop, working on some of the body shape on the BT52.’ When Murray moved to McLaren and eventually to the F1 road-car project, he called Stevens and asked if he knew anyone who might be interested in doing the design. Stevens volunteered over a couple of beers.

3. The suppliers did it for the glory

Murray had a budget of just £8.5m to set up the car company, kit out the building and produce the world’s best driver’s car. It meant that the suppliers had to supply their products for free. As Murray remembers: ‘I was quite bolshy, looking back, because we couldn’t tell anybody what the car would be, at that stage we were engaged with the first major suppliers for wheels and tyres, brakes, glass, that sort of stuff. I’d sit down and I had this spiel worked out where I said “we’re going to build the best engineered car in the world and the best driver’s car in the world, can’t tell you a thing about it at all, but if you want to come on board I need all this stuff for free”. A lot of them walked out, but the ones that stayed, in the end it worked pretty well for them and pretty well for us.’

4. The fan car finally got its revenge

Gordon Murray’s ‘fan car’, the BT46B designed during his time with Brabham, was banned from motorsport for its fan-assisted aerodynamics. Free from those regulations, Murray again put the concept to work on the F1. ‘We had a very short, steep diffuser to get under the driveshafts, and we didn’t want the driveshafts to poke through the diffuser,’ says Murray. ‘So I just steepened it and used fans to suck off the boundary layer, so the air still followed the surface. It was fan-assisted ground effect.’ Don’t say you wouldn’t have done the same.

5. Ron Dennis left them to it

McLaren boss Ron Dennis is often portrayed as a micro-managing control freak with a weird facial hair phobia, but either that’s far from the truth or Dennis has changed beyond recognition in the 25 years since the F1 project kicked off in 1989. Murray and Stevens’ descriptions just didn’t correlate with the stereotype. ‘Ron was extraordinary on this project,’ said Stevens. ‘He didn’t really know any of us on the design team but he trusted us with his money. He just said “okay, get on with it lads, I won’t interfere, I’ll have a look but I probably won’t understand what you’re doing”, and until he saw the finished car, he really didn’t know what we’d been up to. We had 100% support from him, we had a brilliant facility, we didn’t lack any tools or apparatus, we had great food! The McLaren company culture is often criticised from outside, but from within the company the culture is very warm and friendly.’

6. The doors were inspired by a Toyota… and a Porsche

Any time I interview two people involved with the same project separately, I like to ask them exactly the same question and see what happens. It’s a bit of mischief, but often revealing. Here’s what Murray said about the doors: ‘To get into the middle seat we did lots of seating bucks; you had to remove a large section of the roof to be able to swing in, and it was a lot easier if you took a lot of the sill away at the bottom, to be able to sit near the middle of the car and then drop yourself in. I really struggled, and then I saw a styling magazine that had dihedral doors that not only opened a section of the roof, but also cleared the foot-swing area. When we did a mock-up with wire in the workshop, I discovered that you could also take away some of the rocker as well, so that did everything. Then we found a car called the Toyota Sera, and it actually had those doors so we brought it in. The way we did it, removing part of the floor, was original, but it had already been done.’

And here’s what Stevens said: ‘We all agreed that when the doors opened, it should be a little bit of theatre. We saw a little Toyota show car, which had some interesting angled upwards doors, and I’d also worked on Porsche’s 962, and I knew that they stayed closed at 220mph; you need a very strong roof to do that, which we had. At that time we had a scale wind-tunnel model of the car and we were just thinking of how the door would open, so we made a little welding rod wire-frame shape of the door with a couple of staples in to the body and we quickly found a geometry that worked.’ Essentially the same story, but Murray and Stevens’s slightly different recollections are interesting.

7. Murray didn’t think it was too fast; Stevens wondered if it was

Just like the question above, I asked both Murray and Stevens the same thing, but separately. This time I asked if they ever felt a moral responsibility for putting something powerful on the road. ‘Not really, no,’ said Murray. ‘I’m a motorcyclist, I’ve been riding for 52 years, and my reckoning was you can buy something that weighs 180kg with 170bhp, that would out-accelerate any supercar, with no ABS, no traction control, no anything, and people accept that.’

Stevens was a little more tentative: ‘We worked out that if you’re on the autobahn doing over 200mph and a truck pulls out half a kilometre ahead, you’ll hit it. Doesn’t matter what car you’re in, what brakes you’ve got, so that’s a real lesson in reality, you’ve got to dodge round it, because you ain’t going to be able to stop. We had those kind of conversations with the team, which was quite stimulating! And it does focus you because you’re inviting someone to get in this thing and it’s bloody quick, there’s a lot of responsibility in that and I’m glad we all took that so seriously.’

8. The tyres were a nightmare

Both Michelin and Goodyear developed bespoke tyres for the F1, but the timeframe meant the tyre spec was being honed at the same time as the suspension. ‘Although I’d done tyre work before, I had no idea what a huge influence on steering feel the sidewall construction has,’ admits Murray. ‘So we’d just get something right on the geometry and spring and damper rates and then you’d change the tyres and it would get far worse or far better.’

Remember those words the next time you take your F1 to Kwik Fit and get tempted by the Nanyams.

9. The world’s fastest car almost didn’t have an engine

Murray’s Plan A was for the F1 to have a Honda engine. It was entirely logical: McLaren F1 cars raced with Honda engines, and discussions got quite advanced, with Murray travelling twice to Japan. The plans were for either a 4.5-litre V10 or V12, but then all that changed. ‘Suddenly someone in Honda marketing decided that with the next crop of Hondas coming out – I think a 3.0-litre V6 was going to be their biggest engine –this was going to be a step too far from a marketing point of view,’ says Murray. It got to the stage where the F1 was designed with a space for the engine, no-one knowing quite what would fill it. Then, in 1990, Murray walked past the BMW garage after the Hockenheim Formula 1 race, where he spotted engine genius Paul Rosche having an after-hours beer. ‘He was a mate from my days at Brabham,’ remembers Murray. ‘He said “I’ll do you an engine”!’ Less than two years later, the McLaren F1 had a bespoke BMW V12.

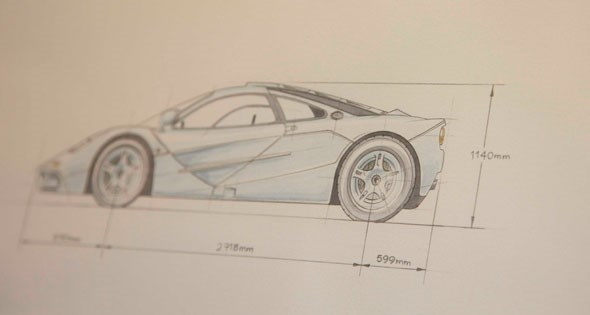

10. The development timeframe was tiny

Most cars take around four years to develop, usually by experienced car companies with existing facilities, vehicle platforms, supplier chains and staff. Murray says he had been thinking of ideas during his last season in F1, 1989. Soon after, he walked into an empty building and, as he puts it, ‘got to do the design of the building, the layout, the plants, the pictures, and pick the whole team from scratch.’ Then, on 23 December 1992, Murray drove the first McLaren F1 prototype. Never mind 3.2 seconds to 60mph. Sub three years from zero to McLaren F1 is pretty blooming speedy.